Vertical Roller Mill In Bermuda

.jpg)

Vertical roller mills FLSmidth Cement

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest The roller press features two opposing rolls rotating at a relatively low speed One Roller Presses2024年1月9日 Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest OK™ Raw and Cement Mill FLSmidth CementAt Magotteaux we are among the leading suppliers of vertical roller mill parts with a presence in many countries around the world With our own research and development programs and an Vertical Roller Mill Magotteaux2019年10月30日 In the 1970s, Vertical Roller Mills (VRMs) became increasingly dominant for grinding raw materials, mainly for the cement and power industries, due to their high energy Vertical Roller Mill (VRM) Castolin EutecticFor raw materials and cement clinker, the vertical roller mill is an excellent grinding solution due to its relatively low installation cost, ease of operation and maintenance, energy savings, and Vertical roller mill DARKO

VRM In Cement Plant Maximize Energy Saving

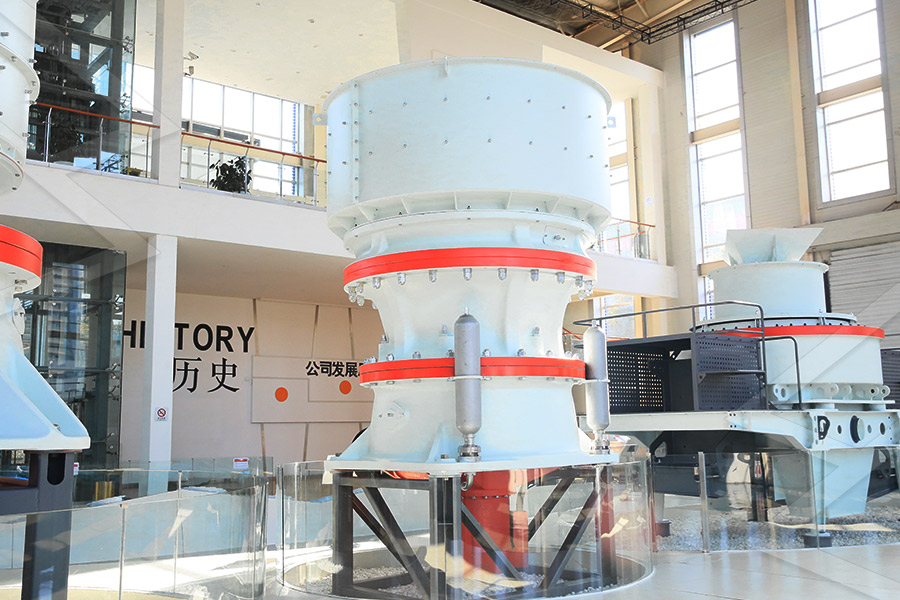

Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding material It integrates grinding, drying, separation, and Advantages of vertical roller mill: The contact surfaces of the grinding plate and the grinding wheel are specially designed to ensure efficient and stable operation The roller hydraulic system has an adjustable spring rate that is applied to the Vertical roller mill Hengtu MachineryOur modern vertical roller mill takes you further Our vertical roller mill offers optimum raw, cement and slag grinding Our bestinclass OK™ Mill is a globally successful vertical roller mill vertical roller mill in bermuda ratidzocoSinomatec vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is suitable for grinding Vertical Roller Mills LNV TECHNOLOGYOur modern vertical roller mill takes you further The OK™ Mill is offered in a complete size range, including 3, 4 and 6roller mills, and the largest vertical roller mill size available with installed vertical roller mill in bermuda thenganilodgeco2025年4月1日 Vertical roller mills operate with grinding rollers that move within a vertical cylinder The grinding table, which is fixed at the base of the machine, rotates and helps to distribute the feed material evenly under the rollers This Exploring the Different Types of Roller Mills

RAYMOND® ROLLER MILLS Thomasnet

2018年7月19日 Raymond Roller Mills: More than 2,000 roller mills have been supplied since the first mills were designed in the late 1800’s These early machines were the forerunner of the heavyduty, rugged ringroll mill manufactured today The roller mill provides the needed flexibility to economically and efficiently process a wide variety of materials2017年8月12日 The inherent design of a vertical roller mill includes classi fiers which are integrated into the machine leading to a variety of positive aspects of the grinding system such as a compact selfsupporting structure, high capacity, low specific energy consumption and an excellent drying capabilLM 696 LM 606 LM 564 LM 536LATEST TECHNOLOGICAL INNOVATIONS IN GRINDING 2019年10月11日 From humble beginnings 113 years ago, family owned business Loesche a has taken the vertical roller mill (VRM) to the forefront of modern day milling This article first appeared in Mining Review Africa Issue 9, 2019 The VRM, depending on the roller size, has a high reduction ratio; feed from 80 mm to 140 mm to a product of P80 at 75 µm in Vertical roller mills: The new leader in grinding technologyUBE Vertical Roller Mill performs drying, grinding, classification and pneumatic transportation simultaneously Material is fed at a constant rate through the chute and fall into the center of table Then the material gets carried to periphery of the table by centrifugal action and is crushed between the rotating grinding track and the grinding VRM – AMCL Machinery Limited2024年5月24日 Vertical roller mills are traditionally airswept mills A VRM applies a compressive force using fixed rollers pressing downwards on a rotating grinding table The material to be ground is fed into the centre of the grinding table via a feed chute From there it forms a material bed which passes under the rollers andVertical Roller Mills used for the comminution of mineral 2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the (PDF) Performance Evaluation of Vertical Roller Mill in

.jpg)

VRM PPT SlideShare

2013年8月8日 The vertical roller mill uses rollers to grind raw materials into a fine powder 2 The ground material is separated inside the mill, with fine material removed and coarse material recycled for further grinding 3 Key components include the grinding table, rollers, drive system, classifier, and separator, which work together to grind and 2024年12月11日 2 VERTICAL ROLLER MILLS INTERNATIONAL CEMENT REVIEW SEPTEMBER 2021 played by the mill foundation, which has been optimised to reduce vibrations2 Built to last The mill foundation, ie, the basic block with its four concrete pylons, is responsible for the smooth running of the mill The roller units and mill housing are notVERTICAL ROLLER MILLS A holistic VRM approach2017年8月12日 vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and mostPROCESS OPTIMISATION FOR LOESCHE GRINDING 2025年2月14日 The document discusses the layout, calculations, components, and heat balance of a vertical roller mill (VRM) There are two basic layouts product collection in cyclones or a filter Key calculations include power Vertical Mill Calculations PDF Mill (Grinding)Vertical roller mills are large grinding machines developed, designed and manufactured by Sinomatec; Sinomatec vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is suitable for grinding materials of different types and sizesVertical Roller Mills LNV TECHNOLOGY2021年1月1日 Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have saved the specific power by 45–70% when compared with a ball mill circuit [8], [10] Now a days Ball mills and HPGR are installed together as a common unitReview on vertical roller mill in cement industry its

.jpg)

LOESCHE Receives Cement Vertical Roller Mill Order from

2024年12月21日 An LM 533+3 CS will be used, with three main and three support rollers and a drive power of 4,650kW The mill will grind clinker and slag at a capacity of 180t/h in a newlybuilt grinding plant belonging to SSCML in Shikalbaha near Chittagong The scope of delivery for both mills includes the complete mill including the static mill componentsVertical roller mills grinding an OPC of low fineness, say around 3000 cm2/g (Blaine) can operate without grinding aid, but even when grinding to that low fineness, grinding aid improves the output rate as well as the specific energy consumption Recent experience has shown that water has an effect similar to that of a grinding aidCement grinding Vertical roller mills VS ball mills2016年1月4日 Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US$=¥110] Related matters Vertical roller mill for raw Application p rocess materialsVertical Roller Mill for Cement, Clinker, Slag, etc See details Release time 20/10/2017 Superfine Powder Vertical Roller Mill See details Release time 19/01/2015 Carbon black grinding mill, processing line See details Release time 18/12/2014 Clirik Newest super fine HGM100 vertical powder grinding millvertical roller mill clirikultrafine vertical mill, Raymond vertical 2025年2月18日 At our powerful national key laboratory, CITIC HIC has established a vertical roller mill testing platform to conduct trials and tests of different materials, thus identifying the best solution of vertical roller mill selection Our engineers employ FEA software to analysis, calculate and optimize the structural strength of grinding roller Vertical Roller Mills Cement Processing Equipment CITIC HIC2023年7月4日 The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power industry, the preparation of nonmetallic ore ultrafine powder, manganese ore Roller Mill SpringerLink

.jpg)

vertical roller mill in bermuda kooksco

Vertical Roller mill has two pairs of grinding rollers, each pair of roller composed of two narrow rollers, mounted on the same axis and can rotate at different speeds The materials fall into the center of device through lock air feeder, and hot air comes into mill through air inlet under the function of centrifugal force, the materials when 2021年1月1日 With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over the ball mill system [10] A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical Review on vertical roller mill in cement industry its 2019年9月17日 VRM operations Free download as PDF File (pdf), Text File (txt) or view presentation slides online The document provides information on controlling parameters for a vertical roller mill (VRM) system It discusses how VRM Operations PDF Nozzle Mill (Grinding)2023年1月19日 The vertical roller mill uses rollers to grind raw materials into a fine powder 2 The ground material is separated inside the mill, with fine material removed and coarse material recycled for further grinding 3 Key components OptimizationofVerticalRawMillOperationpdf 2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries In this study, the discrete element method (DEM) was employed to explore the crushing in an overflow VRM without air involved via the bondedparticle model (BPM) Particle crushing experiments on a laboratoryscale VRM were Analysis of vertical roller mill performance with changes in 2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding Operational parameters affecting the vertical roller mill

Roller Mill Springer

2023年7月4日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can be divided into vertical roller mill, horizontal cylinderrollermill,highpressurerollermill,Raymond mill, and column mill Vertical Roller Mill2015年3月25日 The hydraulic system of vertical mill is an important system, the main function of the hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sides of the grinding roller mill, Hydraulic system vertical roller mill operation PDF2025年4月2日 LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low failure rate of our mills The roller grinding mill technology, patented in 1928 and continuously developed since then, has Cement Industry LoescheThe Vertical Roller Pregrinding Mills developed by AMCL Machinery Limited are based on technical knowhow from Nihon Cement Co Ltd Japan These machines are used for substantial power saving and capacity enhancement in the field of Clinker and Raw meal Grinding We have over two decades of experience in supply and installations of Vertical VRPM – AMCL Machinery LimitedContribute to yunan88/crusher development by creating an account on GitHubcrusher/sbm roller vertical roller mill in bermudamd at main2025年4月1日 Vertical roller mills operate with grinding rollers that move within a vertical cylinder The grinding table, which is fixed at the base of the machine, rotates and helps to distribute the feed material evenly under the rollers This Exploring the Different Types of Roller Mills

RAYMOND® ROLLER MILLS Thomasnet

2018年7月19日 Raymond Roller Mills: More than 2,000 roller mills have been supplied since the first mills were designed in the late 1800’s These early machines were the forerunner of the heavyduty, rugged ringroll mill manufactured today The roller mill provides the needed flexibility to economically and efficiently process a wide variety of materials2017年8月12日 The inherent design of a vertical roller mill includes classi fiers which are integrated into the machine leading to a variety of positive aspects of the grinding system such as a compact selfsupporting structure, high capacity, low specific energy consumption and an excellent drying capabilLM 696 LM 606 LM 564 LM 536LATEST TECHNOLOGICAL INNOVATIONS IN GRINDING 2019年10月11日 From humble beginnings 113 years ago, family owned business Loesche a has taken the vertical roller mill (VRM) to the forefront of modern day milling This article first appeared in Mining Review Africa Issue 9, 2019 The VRM, depending on the roller size, has a high reduction ratio; feed from 80 mm to 140 mm to a product of P80 at 75 µm in Vertical roller mills: The new leader in grinding technologyUBE Vertical Roller Mill performs drying, grinding, classification and pneumatic transportation simultaneously Material is fed at a constant rate through the chute and fall into the center of table Then the material gets carried to periphery of the table by centrifugal action and is crushed between the rotating grinding track and the grinding VRM – AMCL Machinery Limited2024年5月24日 Vertical roller mills are traditionally airswept mills A VRM applies a compressive force using fixed rollers pressing downwards on a rotating grinding table The material to be ground is fed into the centre of the grinding table via a feed chute From there it forms a material bed which passes under the rollers andVertical Roller Mills used for the comminution of mineral 2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the (PDF) Performance Evaluation of Vertical Roller Mill in

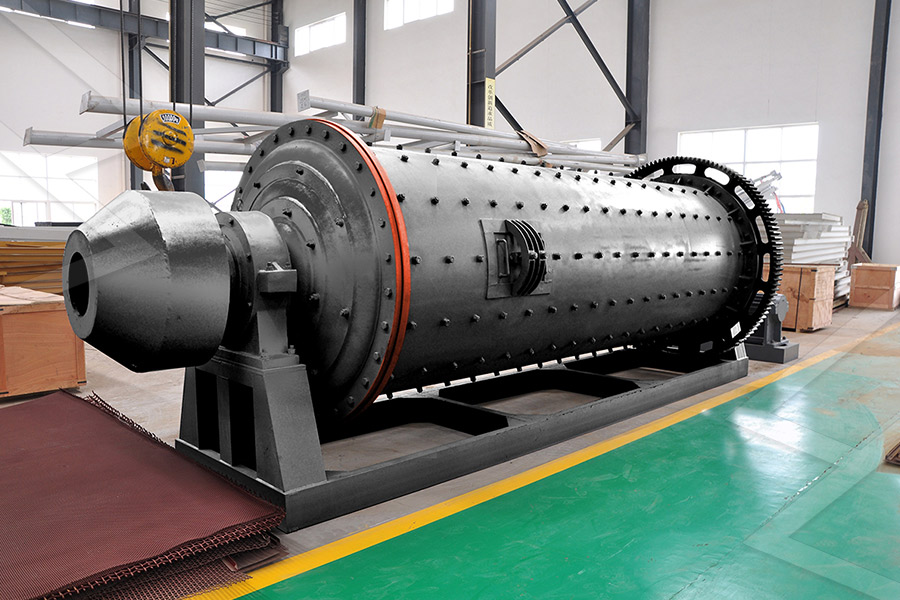

.jpg)

VRM PPT SlideShare

2013年8月8日 The vertical roller mill uses rollers to grind raw materials into a fine powder 2 The ground material is separated inside the mill, with fine material removed and coarse material recycled for further grinding 3 Key components include the grinding table, rollers, drive system, classifier, and separator, which work together to grind and 2024年12月11日 2 VERTICAL ROLLER MILLS INTERNATIONAL CEMENT REVIEW SEPTEMBER 2021 played by the mill foundation, which has been optimised to reduce vibrations2 Built to last The mill foundation, ie, the basic block with its four concrete pylons, is responsible for the smooth running of the mill The roller units and mill housing are notVERTICAL ROLLER MILLS A holistic VRM approach2017年8月12日 vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and mostPROCESS OPTIMISATION FOR LOESCHE GRINDING